Product Maintenance

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arcu convallis placerat. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arcu convallis placerat. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arcu convallis placerat.

Avoiding Damage

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arcu convallis placerat. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arcu convallis placerat. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arcu convallis placerat.

Common Issues & Solutions

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arcu convallis placerat. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arc.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arcu convallis placerat. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arc.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arcu convallis placerat. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arc.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arcu convallis placerat. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arc.

Perforating Technology

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arcu convallis placerat. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arc.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arcu convallis placerat. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arc.

Punch durability is largely dependent upon induced stress levels (relative to the ultimate strength of the component material). Due to the nature of applied loads, breakage generally occurs during the perforating process, whereas, most cutting-edge wear develops during stripping.

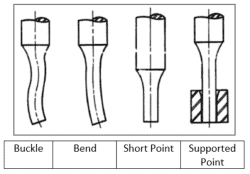

For perforating punches, head breakage is a serious concern. Often times, this concern can be mitigated by increasing the shank diameter so that the load is distributed over a larger area, thereby reducing the stress value.Another concern is bending or buckling problems, which can develop as a result of the magnitude of deflection and its propensity to increase component length.

Improved punch durability can sometimes be achieved by a blend radius that reduces stress concentration in critical areas. For example, cutting edge chipping can be reduced or eliminated by stoning a .002” to .004” radius or chamfer on the component. This procedure effectively increases the contact area resulting in a lower stress level.

Frictional force is equal to the stripping load and directly related to the rate at which the component cutting edges erode. Factors impacting the magnitude of frictional force and, consequently, wear rate are expressed in the following formula: F = uN where F = Force of Friction (lbs.), u = Coefficient of Friction, and N = Normal Force (lbs.)

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arcu convallis placerat. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Phasellus nec elementum mi. Fusce pharetra sed arc.