Tipco Capabilities

Tipco has a diverse range of manufacturing capabilities throughout its facilities. Tipco’s core work centers include CNC soft-turning lathes, CNC hard-turning lathes, CNC 5-axis milling, CNC 5-axis shape grinding, CNC form grinding; surface grinding, centerless grinding, and Wire EDMs. In addition, Tipco has its own internal heat treating department. Tipco’s inspection department also has a wide range of inspection equipment – including image measurement systems and CMMs. Tipco’s wide range of manufacturing capabilities help ensure the company is able to provide competitive prices and lead times on both standard and custom designed tooling.

Turning

Wire EDM

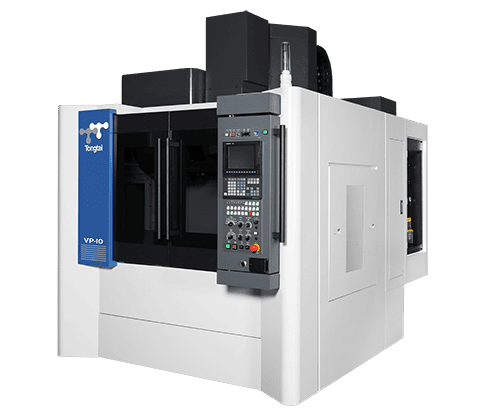

Milling

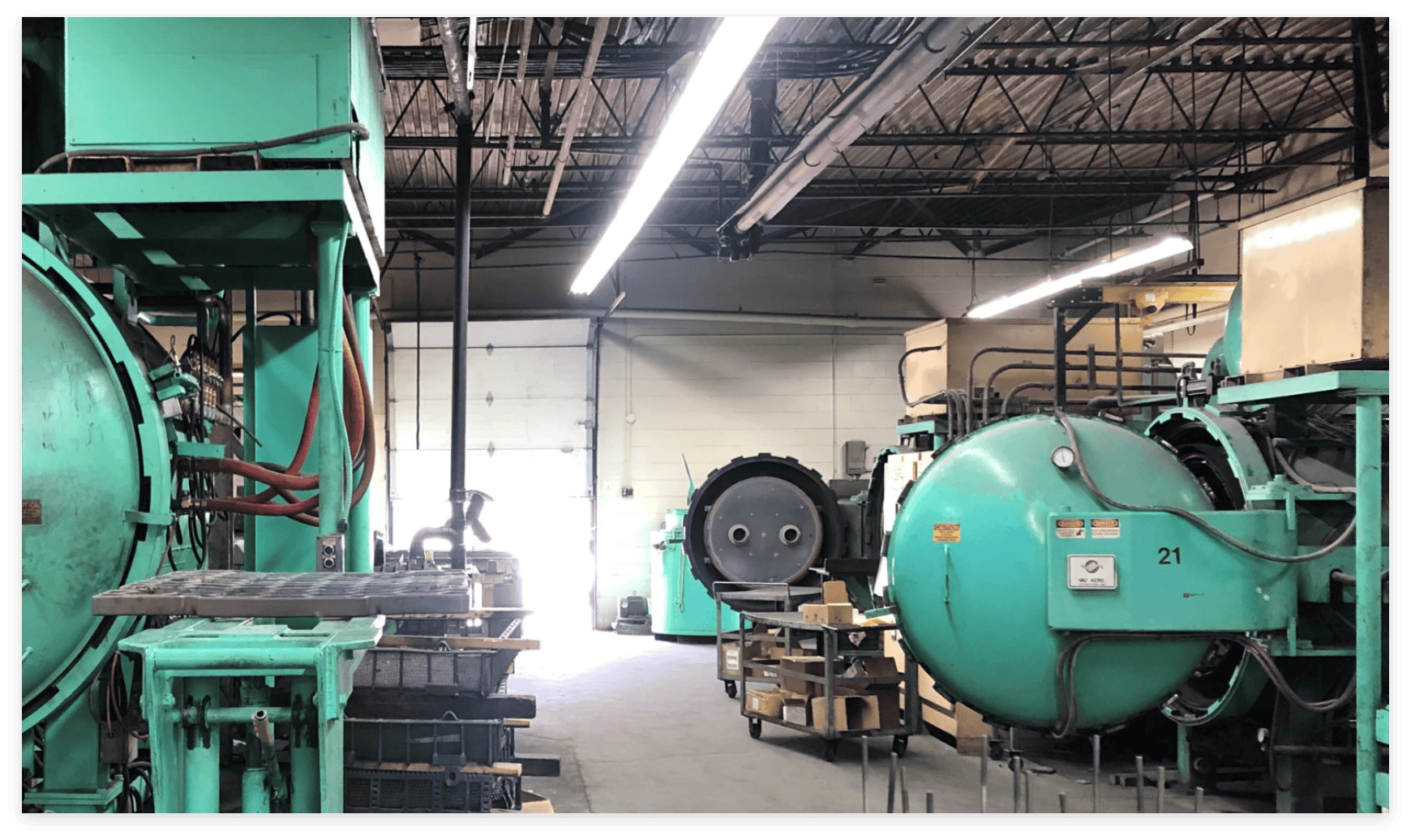

Heat Treating

Grinding

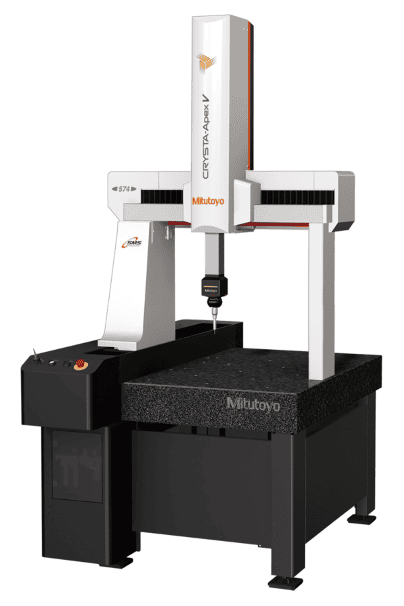

Inspection

Machinery & Equipment

Tipco’s machinery and equipment list includes – but is not limited to – the following: CNC swiss-type lathes; CNC turret lathes; CNC 5-axis mills; CNC form grinders; CNC shape grinders; surface grinders; centerless grinders; wire EDMs; and, heat treat furnaces. Tipco specializes in manufacturing high-precision tooling components, which means that most of Tipco’s CNC machines can work with tolerances of 0.0002 (5µ).

Work Centers & Facilities

Tipco has manufacturing facilities in Canada, U.S.A, and U.K. Tipco’s three manufacturing facilities have a wide range of manufacturing capabilities, including – but not limited to – the following work centers: CNC soft turning (lathes); CNC hard turning (lathes); CNC milling; CNC shape grinding; CNC form grinding; surface grinding; centerless grinding; and, wire EDM. In addition, Tipco has its own internal heat treating department.