Performance Coatings

Tipco offers multiple PVD coating options for customer applications. PVD coatings offer many benefits, including – but not limited to – the following: substrate tool maintenance; improved tool life; abrasion resistance; and, galling resistance. A few examples of common PVD coatings include: Titanium Nitride (TiN); Titanium Carbonitride (TiCN); Chromium Nitride (CrN); and, Titanium Aluminum Nitride (TiALN). Additional coating solutions are available upon request.

Performance Coatings

Tipco provides a wide range of coating PVD options. Different Tipco PVD coating solutions include – but are not limited to – the following: TiN; TiCN; CrN; and, TiALN. See the tables below for different PVD coating details and information. Additional PVD coatings are available upon request.

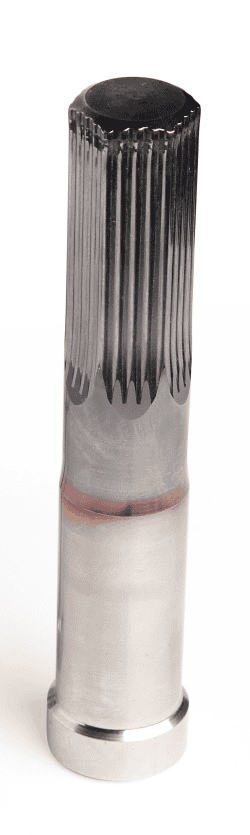

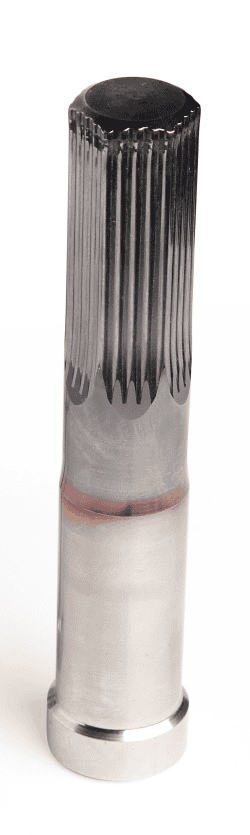

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| TiN | Titanium Nitride | Gold | Characteristics: Standard all-purpose coating | Metal Forming; Plastic Molding | |

| Micro-hardness (Range): Light-Medium | |||||

| Micro-hardness (HV): 2200 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.6 | |||||

| Coating Thickness Max. (μm): 10 |

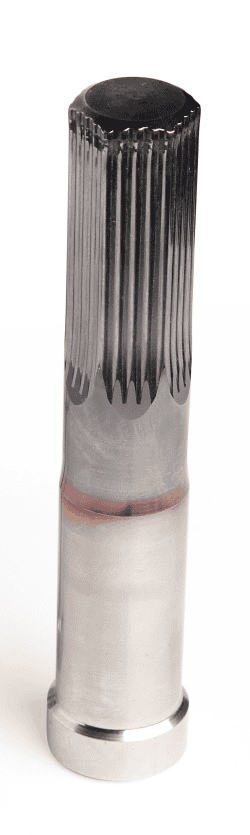

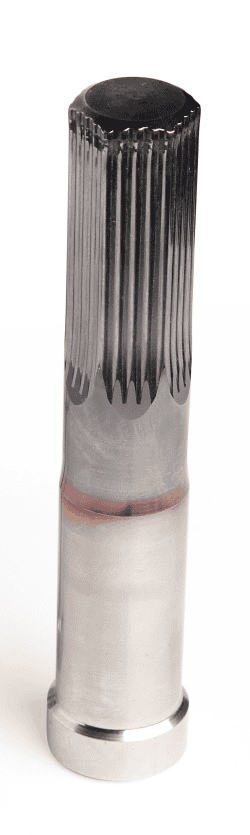

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| TiCN | Titanium Carbo-Nitride | Grey / Bronze | Characteristics: High hardness; Good abrasive wear resistance; enhanced toughness | High-performance cutting; Great for metal forming (stainless steel) | |

| Micro-hardness (Range): Heavy | |||||

| Micro-hardness (HV): 3400 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.2 | |||||

| Coating Thickness Max. (μm): 6 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| TiAlN | Titanium Aluminum | Anthracite | Characteristics: High hardness; Good oxidation resistance | High speed operations; Semi-dry or dry machining | |

| Micro-hardness (Range): Heavy | |||||

| Micro-hardness (HV): 3200 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.7 | |||||

| Coating Thickness Max. (μm): 10 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| TiAlCN | Titanium Aluminum Carbo-Nitride | Old Rose | Characteristics: Low friction; High oxidation resistance | Drawing; Stamping; Punching; Forming tools | |

| Micro-hardness (Range): Heavy | |||||

| Micro-hardness (HV): 3500 ± 500 | |||||

| Friction Coefficient (dry over steel): 0.2 | |||||

| Coating Thickness (μm): 2-4 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

|

CrN | Chromium Nitride | Silver / Grey | Characteristics: Low stress (good adhesion); High toughness; High corrosion resistance | Metal Forming; Plastic Molding |

| Micro-hardness (Range): Light | |||||

| Micro-hardness (HV): 2000 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.3 – 0.4 | |||||

| Coating Thickness Max. (μm): 12 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

|

AlCrN | Aluminum Chromium Nitride | Slate / Grey | Characteristics: Extreme hot hardness; High oxidation resistance; High adhesive strength | Punching; Forming; High Performance Cutting, Hobbing, Dry Broaching |

| Micro-hardness (Range): Medium – Heavy | |||||

| Micro-hardness (HV): 3200 ± 300 | |||||

| Friction Coefficient (dry over steel): 0.45 | |||||

| Coating Thickness (μm): 2 – 5 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| TiN | Titanium Nitride | Gold | Characteristics: Standard all-purpose coating | Metal Forming; Plastic Molding | |

| Micro-hardness (Range): Light-Medium | |||||

| Micro-hardness (HV): 2200 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.6 | |||||

| Coating Thickness Max. (μm): 10 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| TiCN | Titanium Carbo-Nitride | Grey / Bronze | Characteristics: High hardness; Good abrasive wear resistance; enhanced toughness | High-performance cutting; Great for metal forming (stainless steel) | |

| Micro-hardness (Range): Heavy | |||||

| Micro-hardness (HV): 3400 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.2 | |||||

| Coating Thickness Max. (μm): 6 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| TiAlN | Titanium Aluminum | Anthracite | Characteristics: High hardness; Good oxidation resistance | High speed operations; Semi-dry or dry machining | |

| Micro-hardness (Range): Heavy | |||||

| Micro-hardness (HV): 3200 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.7 | |||||

| Coating Thickness Max. (μm): 10 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| TiAlCN | Titanium Aluminum Carbo-Nitride | Old Rose | Characteristics: Low friction; High oxidation resistance | Drawing; Stamping; Punching; Forming tools | |

| Micro-hardness (Range): Heavy | |||||

| Micro-hardness (HV): 3500 ± 500 | |||||

| Friction Coefficient (dry over steel): 0.2 | |||||

| Coating Thickness (μm): 2-4 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

|

CrN | Chromium Nitride | Silver / Grey | Characteristics: Low stress (good adhesion); High toughness; High corrosion resistance | Metal Forming; Plastic Molding |

| Micro-hardness (Range): Light | |||||

| Micro-hardness (HV): 2000 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.3 – 0.4 | |||||

| Coating Thickness Max. (μm): 12 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

|

AlCrN | Aluminum Chromium Nitride | Slate / Grey | Characteristics: Extreme hot hardness; High oxidation resistance; High adhesive strength | Punching; Forming; High Performance Cutting, Hobbing, Dry Broaching |

| Micro-hardness (Range): Medium – Heavy | |||||

| Micro-hardness (HV): 3200 ± 300 | |||||

| Friction Coefficient (dry over steel): 0.45 | |||||

| Coating Thickness (μm): 2 – 5 |

Advanced High-Performance Coatings

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| CRALON-M | AlCRTiSiN Based | Bronze | Characteristics: Multi-layer; Duplex; Triplex | ||

| Micro-hardness (Range): | |||||

| Micro-hardness (HV): 3400 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.2 | |||||

| Coating Thickness Max. (μm): 8 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| CRALON-S | TiAlVSiN Based | Bronze | Characteristics: Multi-layer; Duplex; Triplex | ||

| Micro-hardness (Range): | |||||

| Micro-hardness (HV): 3500 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.2 | |||||

| Coating Thickness Max. (μm): 8 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| FORMALL (V10) | VCN Based | Yellow | Characteristics: Single layer; Duplex; Gradient | Universal coating for hot and cold roll applications; Excellent toughness properties | |

| Micro-hardness (Range): | |||||

| Micro-hardness (HV): 3000 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.5 | |||||

| Coating Thickness Max. (μm): 20 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| FORMALL-S | TiSiVN Based | Bronze | Characteristics: Multi-layer; Duplex; Triplex | Good for demanding applications; Multi-layer coating used in HSLA applications; Superior wear protection and adhesion properties | |

| Micro-hardness (Range): | |||||

| Micro-hardness (HV): 3500 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.2 | |||||

| Coating Thickness Max. (μm): 10 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| D-ARC | DLC (Diamond Like Carbon) | Gray – Black | Characteristics: Multi-layer; Duplex | ||

| Micro-hardness (Range): | |||||

| Micro-hardness (HV): 4000 ± 200 | |||||

| Friction Coefficient (dry over steel): < 0.1 | |||||

| Coating Thickness Max. (μm): 4 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| D-ARC Nano | DLC (M) Based | Grey – Black | Characteristics: Multi-layer; Duplex; Triplex; Gradient | ||

| Micro-hardness (Range): | |||||

| Micro-hardness (HV): 4000 ± 200 | |||||

| Friction Coefficient (dry over steel): < 0.1 | |||||

| Coating Thickness Max. (μm): 10 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| CRALON-M | AlCRTiSiN Based | Bronze | Characteristics: Multi-layer; Duplex; Triplex | ||

| Micro-hardness (Range): | |||||

| Micro-hardness (HV): 3400 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.2 | |||||

| Coating Thickness Max. (μm): 8 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| CRALON-S | TiAlVSiN Based | Bronze | Characteristics: Multi-layer; Duplex; Triplex | ||

| Micro-hardness (Range): | |||||

| Micro-hardness (HV): 3500 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.2 | |||||

| Coating Thickness Max. (μm): 8 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| FORMALL (V10) | VCN Based | Yellow | Characteristics: Single layer; Duplex; Gradient | Universal coating for hot and cold roll applications; Excellent toughness properties | |

| Micro-hardness (Range): | |||||

| Micro-hardness (HV): 3000 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.5 | |||||

| Coating Thickness Max. (μm): 20 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| FORMALL-S | TiSiVN Based | Bronze | Characteristics: Multi-layer; Duplex; Triplex | Good for demanding applications; Multi-layer coating used in HSLA applications; Superior wear protection and adhesion properties | |

| Micro-hardness (Range): | |||||

| Micro-hardness (HV): 3500 ± 200 | |||||

| Friction Coefficient (dry over steel): 0.2 | |||||

| Coating Thickness Max. (μm): 10 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| D-ARC | DLC (Diamond Like Carbon) | Gray – Black | Characteristics: Multi-layer; Duplex | ||

| Micro-hardness (Range): | |||||

| Micro-hardness (HV): 4000 ± 200 | |||||

| Friction Coefficient (dry over steel): < 0.1 | |||||

| Coating Thickness Max. (μm): 4 |

| Coating Image | Coating | Coating Material | Color | Key Criteria | Applications |

| D-ARC Nano | DLC (M) Based | Grey – Black | Characteristics: Multi-layer; Duplex; Triplex; Gradient | ||

| Micro-hardness (Range): | |||||

| Micro-hardness (HV): 4000 ± 200 | |||||

| Friction Coefficient (dry over steel): < 0.1 | |||||

| Coating Thickness Max. (μm): 10 |

Coating Materials

Coating applications provide several advantages that enhance the performance and longevity of tools. Some of the key benefits of applying coatings include the following: improved performance; extended tool life; higher productivity; reduced downtime; reduced maintenance costs; reduced tool adhesion; improved cost efficiency; improved corrosion resistance; and, enhanced heat resistance. Overall, coating technologies can be a key factor in helping increase productivity and reducing operational costs.